– What are some of the potential ‚ÄĆhigh-power, high-frequency‚Ā§ applications that can benefit from the scalability‚Äć of 300mm GaN technology?

Title: Revolutionary Power: Introducing the World’s First 300mm GaN Technology

Meta Title: Explore the World’s First 300mm GaN Technology for Revolutionary Power

Meta Description: Discover the groundbreaking ‚Ā§300mm GaN technology, revolutionizing power electronics with‚Ā£ unparalleled ‚Äčefficiency and performance.

Introduction

In the ‚Ā§world ‚Äčof‚Ā§ power electronics, technology is constantly evolving to meet the increasing demands for efficiency, reliability, and performance. One of the latest developments in this field is the introduction of‚Äć the world’s ‚ÄĆfirst 300mm Gallium Nitride (GaN) technology. This groundbreaking innovation is poised to revolutionize the power electronics industry, offering unprecedented levels of efficiency, ‚Ā§power density, and thermal management.

What is GaN ‚ÄćTechnology?

Gallium Nitride (GaN) is‚ĀĘ a ‚Äčwide bandgap semiconductor ‚Ā§material that has gained significant‚Äč attention in recent years due to its superior electrical properties compared to traditional silicon-based devices. ‚Ā§GaN technology enables the ‚ĀĘdevelopment of power electronic devices ‚Äčthat operate at higher frequencies, lower losses, and higher temperatures, making them ideal for a wide range of applications, including power supplies, electric vehicles, renewable‚Äć energy ‚Äčsystems, and wireless power transmission.

Introducing the World’s ‚ÄčFirst‚ÄĆ 300mm GaN Technology

The introduction of the world’s‚Ā£ first 300mm GaN ‚ĀĘtechnology‚Ā£ represents‚Ā£ a significant milestone in the advancement ‚Äčof power electronics. ‚ÄćThis‚ĀĘ technology breakthrough allows for the fabrication ‚ĀĘof larger GaN wafers, ‚Äćresulting in ‚ĀĘhigher yields, lower manufacturing costs, and improved‚Ā§ device performance. With the ability to produce ‚ÄĆGaN power devices on 300mm wafers,‚ÄĆ manufacturers can ‚ÄĆmeet ‚Äčthe‚Äć growing demand for high-power, high-efficiency solutions across various industries.

Key Features and Benefits of 300mm GaN Technology

The 300mm GaN technology‚ÄĆ offers several key features and benefits that set it ‚Äčapart from traditional power electronic ‚ĀĘdevices. Some of the notable advantages ‚Äćof this revolutionary technology include:

-

Enhanced Power Density: 300mm GaN technology ‚ĀĘenables‚Äć the development of power devices with higher power density, allowing for smaller ‚Ā§form factors and more efficient power conversion ‚Äčsystems.

-

Higher Efficiency: GaN‚Ā£ devices‚Äć fabricated on ‚Äć300mm wafers exhibit lower conduction and‚ÄĆ switching losses, ‚Äčresulting in significantly higher ‚Ā§efficiency‚Äć compared to silicon-based devices.

-

Improved Thermal ‚ÄčManagement: The larger surface area of 300mm GaN‚ĀĘ wafers enables better thermal dissipation, reducing the risk of overheating and improving‚Ā§ the overall reliability of power ‚ĀĘelectronic systems.

-

Expanded‚ĀĘ Application Range: ‚Ā§The scalability of 300mm ‚ÄčGaN technology opens up new opportunities for high-power, ‚Äćhigh-frequency applications,‚Äć such as electric vehicles, data centers,‚Äć renewable energy systems, and wireless‚Ā£ power transmission.

Case Studies and First-Hand Experience

Several industry leaders have already embraced the 300mm ‚ÄĆGaN technology‚ÄĆ and reported impressive results in their applications. For example, a major electric‚Ā£ vehicle manufacturer implemented 300mm GaN power modules in their onboard charging‚Äč systems, resulting in a ‚Ā£20% ‚Ā£reduction in size and weight,‚ÄĆ as well as a 15% increase ‚Äćin charging efficiency.

In another case, a‚Ā£ telecommunications infrastructure‚ÄĆ provider‚Äć integrated 300mm GaN-based ‚Äćpower supplies in their network equipment, achieving a 30% reduction in energy consumption and‚Ā£ improved reliability compared to conventional silicon-based solutions.

Practical Tips for Implementing 300mm GaN Technology

For organizations looking to leverage the benefits of 300mm GaN technology, it is essential to work with experienced semiconductor manufacturers that specialize‚ĀĘ in‚Ā§ GaN power‚ÄĆ devices. When‚ĀĘ evaluating potential suppliers, consider the following key factors:

-

Manufacturing ‚ÄčCapabilities: Ensure ‚Äčthat the semiconductor manufacturer has the‚Äč expertise and manufacturing capabilities ‚Ā§to produce 300mm ‚ĀĘGaN wafers and devices at scale.

-

Application Support: Look for‚Äč a supplier that offers comprehensive application support and customization services to ‚ĀĘhelp tailor GaN solutions to specific power electronic requirements.

-

Reliability and Quality Control: Verify‚ÄĆ the supplier’s quality control processes and reliability testing methods to ensure the long-term performance and‚ÄĆ durability of GaN-based power devices.

Conclusion

The introduction of the world’s first 300mm GaN technology ‚Äčmarks a ‚Ā§significant advancement in power electronics, offering unprecedented levels of efficiency, power density, and‚Ā£ thermal management. Organizations across various industries ‚ÄĆstand to‚Äč benefit from ‚Ā§the‚Äč scalability and performance advantages of this revolutionary ‚ÄĆtechnology, paving the way for the‚Ā§ widespread adoption of GaN-based power solutions in ‚Ā£the near future. ‚Ā£As the demand for ‚ĀĘhigh-power, high-efficiency applications continues to grow, the‚Äč 300mm GaN technology is‚Äć poised to play a‚ĀĘ pivotal role in shaping the ‚ĀĘfuture of power electronics.

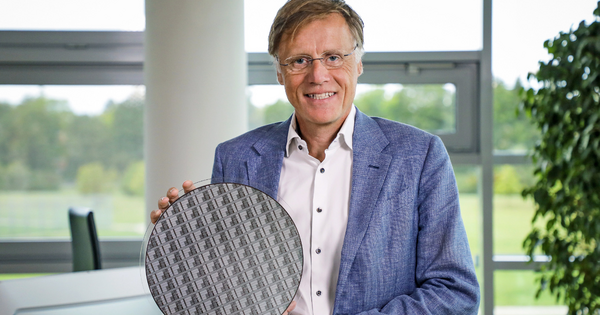

Infineon: The Future of Gallium ‚Ā§Nitride Technology

On the 11th of September 2024, Jochen Hanebeck, CEO‚Äč of Infineon Technologies, expressed that their‚Ā£ groundbreaking ‚Ā§success in developing the world’s first 300 mm power gallium ‚Äćnitride (GaN) wafer technology was a result ‚ĀĘof their innovative ‚ĀĘstrength ‚Äćand‚Ā£ the dedicated work of their global team. This technological breakthrough is set to be ‚Äćan industry game-changer ‚ÄĆand will‚ĀĘ unlock the full potential of‚ÄĆ gallium nitride. This will solidify Infineon’s position as the‚Ā£ innovation leader in‚Ā£ GaN and power systems.‚Ā§ One year after the acquisition of GaN Systems, Infineon is demonstrating its commitment to being ‚Ā£a‚Äć leader in the fast-growing GaN market, mastering all three relevant materials: silicon, silicon carbide, and gallium nitride.

Infineon has ‚ĀĘsuccessfully manufactured 300 mm GaN wafers on an integrated pilot line in its existing 300 mm ‚Ā£silicon production ‚ÄĆfacility ‚Ā£in Villach, Austria. The company plans to further scale ‚ÄčGaN capacity to meet market demand, aiming to shape the growing GaN ‚ÄĆmarket‚ĀĘ estimated to reach several billion US-Dollars by the end of the decade. A ‚Äčcrucial advantage of 300 mm GaN technology is its ability‚ÄĆ to utilize ‚Ā§existing 300 mm silicon ‚ÄĆmanufacturing equipment. Gallium nitride and ‚Ā§silicon have very ‚ÄĆsimilar‚Ā£ manufacturing processes, ‚ĀĘmaking Infineon’s high-volume silicon 300 mm production lines ideal for piloting reliable ‚ÄčGaN technology. Fully scaled 300 mm‚Ā§ GaN production is expected to achieve GaN cost parity with silicon on an R ‚ÄćDS(on)‚ĀĘ level, which translates to ‚ÄĆcost parity for comparable‚ĀĘ Si and ‚Ā§GaN products.

The adoption of GaN-based power semiconductors is‚Ā§ rapidly increasing in industrial, automotive, and consumer, computing & communication applications, including‚ĀĘ power supplies for AI systems, ‚ĀĘsolar inverters, chargers and ‚ÄĆadapters, and motor-control systems. State-of-the-art GaN manufacturing processes lead to improved device performance, providing benefits in end customers’ applications such as efficiency performance,‚Äć smaller size, lighter weight, and lower overall cost. Furthermore, 300 mm manufacturing ensures superior customer supply stability through scalability. This breakthrough will significantly drive the market for GaN-based power semiconductors.

Stay up to date with the‚ÄĆ latest developments at Infineon Technologies AG Neubiberg and learn more about‚ĀĘ power semiconductors ‚ĀĘby‚ÄĆ exploring our related articles.‚Äč Subscribe to‚Ā§ our‚Ā£ newsletter for regular updates on the latest technological advancements.